Your first choice for engineering and manufacturing services

Our offerings include not only the products themselves but our know-how and the accumulated skills of our personnel. Needless to say, we assure you of the same care and high quality in engineering services that we are so well known for in manufacturing.

You can be assured that your specifications and guidelines will be adhered to, with our combination of experience, knowledge, and diligence. We provide engineering services and consultation in all of our operating areas:

We invite you to arrange for a meeting with one of our technical consultants. We are eager to solve your problems and help with your challenges.

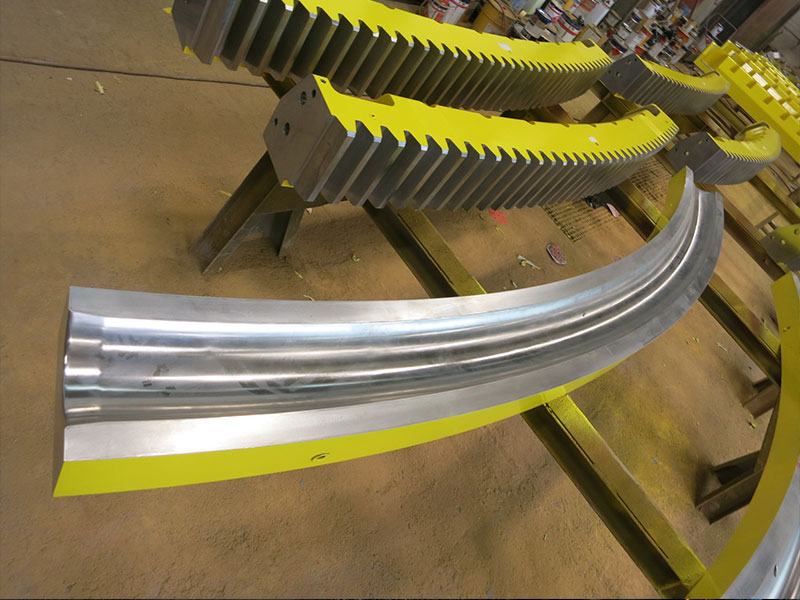

Direct contract services include cutting, turning, and milling

As a manufacturer and service provider, we also offer mechanical precision machining as contract work.

Parameters for machining:

Sawing

Centre lathe turning

length: max. 4,000 mm.

CNC turning

length: max. 6,000 mm

CNC milling

X = 8,000 mm

Y = 800 mm

Z = 500 mm

If you have questions, our technical consultants are at your service.

You can find our service partner here www.turbomech.de

Contract heat treatment including annealing, tempering, hardening, and carburizing

The following processes and equipment are available to serve you:

General heat treatment

Furnaces

Height: max. 800 mm

Depth: max. 1.400 mm

Temperature: max. 1.150 °C

Quenching tanks

| Length | Width | Depth | |

|---|---|---|---|

| Polymer tank | 8.000 mm | 3.000 mm | 3.000 mm |

| Water tank | 8.000 mm | 3.000 mm | 3.000 mm |

Blasting plant

Blasting in accordance with standard SA in closed automatically operating unit with the use of metal shot.

Straightening

1,000 metric ton press, two-standard hammers, or manual straightening apparatus.

Our technical consultants will be only too pleased to answer your questions.